Eduardo Cervantes Lopez, International Consultant in poultry processing, was in charge of the presentation ” Reducing Seizures and Increasing Yields” during the LPN Congress 2018.

Live chickens are the raw material that reaches processing plants to be transformed into meat for our consumption. Therefore, it is important to give it careful handling and to be aware of its environment to reduce the number of situations that can contribute to deteriorating the Grade A Quality, with which it must be shipped to the farms and preserved for a long time during their transport to plants. Failure to do so represents partial and total affectations that become SEIZURES before starting its slaughter.

Introduction

In the same way, in the plants, it must be ensured that the handling the live chickens receive during their processing is adequate. This objective must be complemented with a properly maintained and adjusted technological scenario.

In summary, the SEIZURES that are detected in the plants are the sum of factors that affect the chickens both on the farms and in the plants.

The obligatory question arises: How can this daily goal be achieved?

Knowing the MENTAL MAP of the final part of this business.

To remember the following reflection: “The eyes DO NOT OBSERVE, what the brain DOES NOT KNOW” -Albert Einstein.

Next, some situations observed in various companies will be presented to better illustrate the readers.

During the Pre-slaughter, it is invited to focus attention on the following operations:

Fast

When, for reasons of a different nature, the birds arrive at the plant with insufficient fasting and are sacrificed under these conditions, this specific detail occurs: “Since chickens do not have a diaphragm” – humans do -, when they are hung on the hooks from the slaughter air conveyor, food begins to be pushed back up the esophagus. Since the journeys between the hanged person and the place where the killing occurs are very short, it is impossible to appreciate the discomfort they begin to experience. However, during the bleeding, if it becomes evident. For this reason, it is observed that, surprisingly, many of the birds begin to flutter intensely.

This situation is due to the sensation of suffocation they experience because the feed begins to pressure the trachea, making normal breathing difficult.

When this circumstance occurs, it is suggested to move to the birds’ exit after the last plucker to evaluate the appearance of the crop. You will find that many have a feed.

Pre-collection activities

The daily entry of the personnel responsible for the different houses on a farm is of the most significant importance because the careful way in which it is done will depend on whether the birds are affected in their quality. For this reason, it must be avoided that workers walk inside the houses as they usually do: Quickly. If this small detail is not strictly supervised, the animals will realize a strange element is inside their habitat. Therefore, they begin to retreat in disarray since the presence of at least one person will put them on alert, and their natural reaction is to fly, climbing on the backs of their companions, where they hold on so as not to fall. Consequence: Scratches. If these become infected, they become cellulite, aggravating skin deterioration. Additionally, the intense flapping they generate in their eagerness to get away from that strange element causes bruises on the wings and hemorrhages on the breast. In short, flapping is the Tip of the Seizures Iceberg.

Recommendation:

If the staff walk slowly like chickens, they will not worry and will be in the quiet house. So that is our daily challenge when we do work within them.

Pre-slaughter – Capture and Caging

It is well known that the collection by the legs is the most traumatic method due to the high degree of damage caused to the birds. The first results are from the 180-degree turn that occurs once they have been captured with both hands and their position is changed so that the workers can walk to where the cages are located to place them inside.

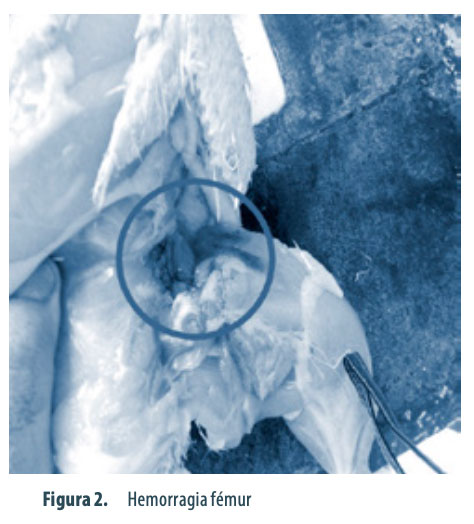

The result of this movement is that some chickens suffer dislocation of the head of the femur in the joint with the acetabulum.

This problem occurs because the femur, due to the way it is embedded in the pelvis, only has horizontal movements.

Consequently, the rotation that the thigh undergoes, in some cases, subjects the femur to a lateral movement that is not possible to do. When this bone is displaced, blood vessels break, whose blood is deposited in its path, forming a hemorrhage.

To reduce this impact on the Grade A quality with which the birds must arrive at the plant, it has been recommended to trap chickens by the body, keeping the wings slightly pressed to the body so that they continue to breathe usually. However, if the dark and quiet environment is not maintained during this operation, the birds will be stressed while the capture is in progress. Therefore, they flap their wings and huddle together to feel safe. In short, this method will not work satisfactorily either. In addition, seizures will increase, as mentioned above.

Chicken cages deserve special care. Chickens are selfish by nature. Once inside the cages, if the new travel companions are not correctly located inside these containers, they also flap, mistreating their wings. This detail may contribute to increasing seizures in this part of the body.

Another aspect to highlight is the risk of using cages without lids. This condition favors the death of many chickens due to skull fracture and hypovolemic shock, as the chickens are pressed when placing these containers, one on top of the other.

- Consequences: Total confiscations

The prolonged loading of cages on trucks and the absence of proper implementation so that chickens remain comfortable during transport and waiting at the plant favor the death of birds due to heat stress. This situation translates into confiscations when they are removed from the cages to hang on the slaughter air conveyor.

For this reason, it is recommended to systematically monitor the MICROENVIRONMENT inside the truck bed to take corrective actions to prevent massive drowning deaths.

Processing

In the plant, there are a series of small details that promote an increase in seizures. The following are mentioned by way of examples:

- Hung on slaughter overhead conveyor. If all the physical and operational infrastructure is not complete and properly adjusted – breast massager, intense flapping occurs once the chicks have been placed on the hooks. This reaction, as mentioned before, results in bruising on the wings and hemorrhages in the breast.

- Aftermath: Partial and Total Confiscations.

- Stunned. When this equipment is installed correctly, and with all its implementations, once the chickens enter the vat, they must put their heads in the water and immediately become unconscious.

If the scenario is not adequate, the PRE-SHOCK problem arises with its costly consequences: Intense flapping during the passage of the birds through the vat. Many of them do not put their heads in the water. For this reason, they come out completely conscious. Wing bruising and breast hemorrhage are exacerbated. All these effects on the quality of the chickens represent partial and total seizures. Additionally, the work of the person located after the automatic slaughterer – Killer – is recharged due to the number of awake chickens that come out of the vat.

In many circumstances, these non-stunned chickens cannot be removed from the hooks at the exit of the Stunner. Once they are slaughtered due to the intense pain they are feeling, they writhe on the hooks and flap their wings a lot. For this reason, the bleeding tunnel is another place where the quality of chickens sent for processing deteriorates.

Scalded and Plucked

These two operations are closely related. Therefore, they must work as a harmonious whole to achieve a high level of effectiveness during the plucking of chickens. But in many plants, the reality is different. For example, chickens partially or totally float during scalding because the variables that govern this phase are not adequately graduated. When birds float, the hardest feathers to remove are on the wings and tail. For this reason, the follicles do not fully dilate. Therefore the feathers do not come off since the protein is not denatured, making it possible to remove it relatively quickly.

Similarly, if the external body heat gained in the scalder is not conserved when the animals leave the scalder, enter the pluckers, and exit these machines, their plucking will not be effective.

In their desire to improve plucking, they increase the water temperature in the scalders and close the pluckers a little more.

Negative results to be obtained:

- Envelope – blanching the breasts

- Envelope – blanching the breasts

- Physical damage to the chickens because the modules where the finger holders are closed increase the degree of friction on the skin with different thicknesses. Also, some areas are weaker than others, especially with no feathers (Apterios).

Yields

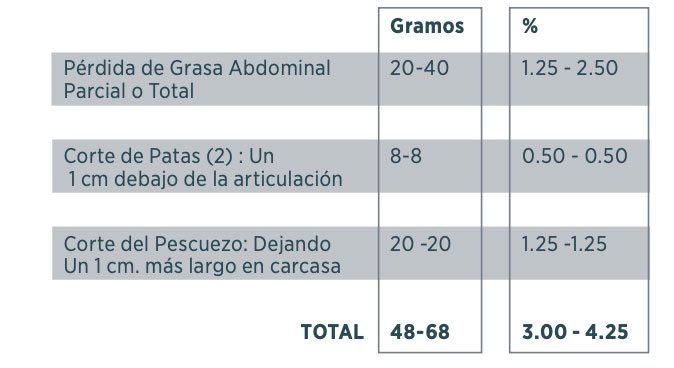

The dry performance of a carcass is established after it has been eviscerated, washed, drained, and checked for quality seconds before being unhooked to the Pre-Chiler or sent to the Air Chilling area. In this place, the yield can oscillate between 72% and 73.75% without a neck, depending on a few minor details suggested to be monitored in real-time to take the respective actions to keep both the seizures and the yield Losses within the established parameters. Here are some situations:

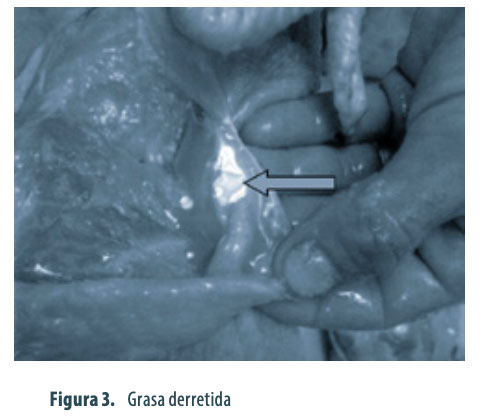

Lastly, if the breast has been over-scalded, the rendered fat is seen as foam floating on top of the water in the chillers. Studies have determined this effective loss of carcass yield between 0.5% and 2.0%, affecting the result of processed chickens.

Conclusions

All factors that Increase confiscations and affect carcass yield with their respective offals must be monitored in the broiler business.